As an important part of the HERMESS team, we are responsible for the signal generation and the installation of the measurement sensors in the ring and to guarantee the fulfilment of the order. For this we work closely with the signal processing team, enabling us to install the components.

The main task here is to install the measuring sensors on the module wall in a manner appropriate to the species. For this purpose, 6 measuring positions were evenly distributed on the ring, each of which is equipped with a measuring unit (STAMP: Strain and Temperature Amplified Measurement Point).

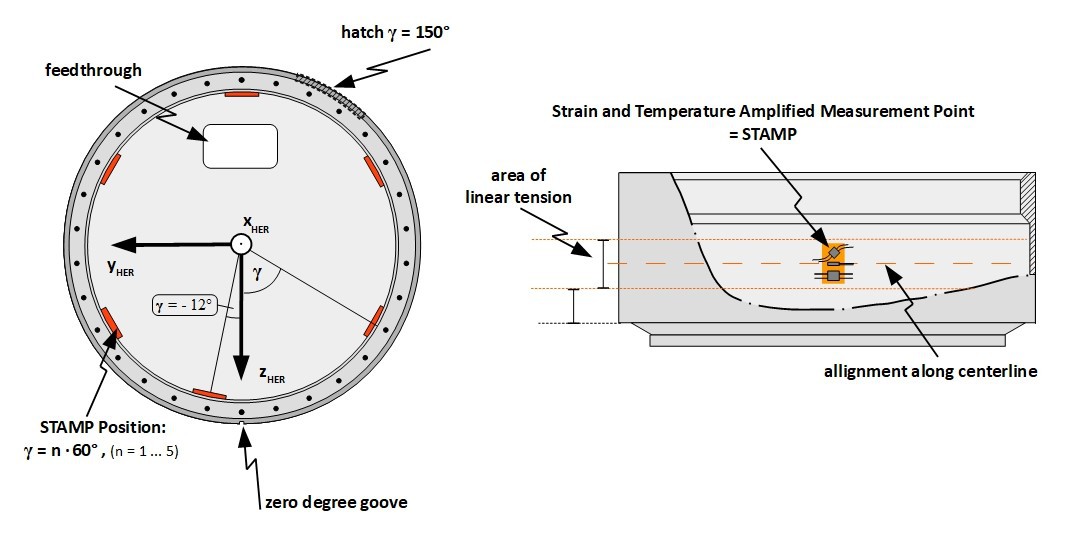

The division of the 6 measuring units is shown in fig. 1.

Fig. 1: Arrangement of the measuring units - short STAMP - in the module.

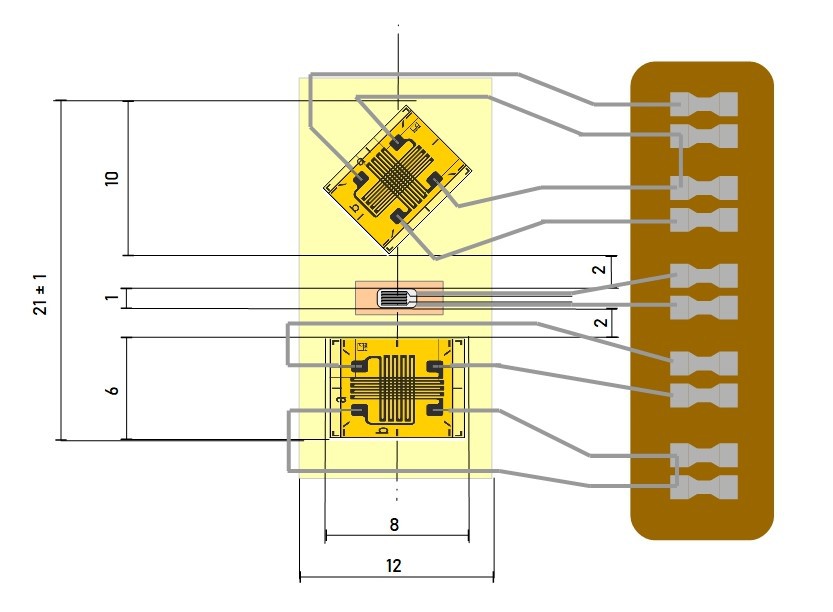

At each position 2 strain gauge rosettes and a temperature sensor are combined to form a STAMP. The detailed orientations are shown in fig. 2. While the strain gauge rosette with a sensor aligned parallel to the longitudinal axis of the rocket detects axial and tangential deformations, the second strain gauge rosette rotated 45° detects the shear components. Placing the temperature sensor close between the two rosettes ensures that the local temperature is measured across both rosettes.

Each STAMP is connected to a nearby fuselage-mounted connector board to form the half-bridge for two strain gages each and relieve the sensitive sensors of the strains that occur during start-up. These in turn are connected to the signal processing units (SPU), which use the four-wire technique for the PT-100 and the V-wire technique for the strain gage rosette half bridges. The techniques used eliminate the influence of wire resistances between SPU and STAMP on the measured values. The cables, plugs and wiring techniques used must be resistant to electromagnetic interference and are currently being tested.

Fig. 2: Arrangement of a STAMP.

Fig. 2: Arrangement of a STAMP.

In addition to the concept of the correct arrangement of the STAMPs, it is the task of the signal generation to realize them and to fix them in the module in a flight-proof way. For this purpose, a gluing method standardized for strain gauges is used which leads to a stable mounting by correct hardening.

This procedure is to be used in the next step to position all STAMPs successfully and thus enable the first test procedures on the module.

In addition, a concept is currently being developed to connect the connections of the sensors to the printed circuit boards in a way that is appropriate to the type of sensor, which will also be glued to the module wall around the sensor arrangement.

This website uses cookies

In order to optimize our website for you and to be able to continuously improve it, we use cookies. In order to be able to fully use the functions of our website, please consent to their use.

Necessary cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

| Name | Provider | Info | Expiry |

|---|---|---|---|

| cookieinfo | Project HERMESS | Saves the user settings for the cookies. | 90 Tage |

| cms144-session | Project HERMESS | Unique ID that identifies the user's session. | Session |

Preference cookies enable a website to remember information that affects the way a website behaves or looks, such as: B. Your preferred language or the region you are in.

| Name | Provider | Info | Expiry |

|---|---|---|---|

| cms144-language | Project HERMESS | Saves the language version of a website selected by the user. | 90 Tage |

Cookies are small text files that are used by websites to make the user experience more efficient.

According to the law, we can store cookies on your device if they are absolutely necessary for the operation of this site. We need your permission for all other types of cookies.

This site uses different types of cookies. Some cookies are placed by third parties that appear on our pages.

You can change or withdraw your consent from the cookie declaration on our website at any time.

Find out more about who we are, how you can contact us and how we process personal data in our privacy policy.

Please include your consent ID and date when contacting us regarding your consent.