The department for Signal Processing is responsible for the signal and data path between signal generation by the sensors and data evaluation after flight or during calibration. This defines our physical interfaces with other systems as the leads of the sensors, the cabling of the rockets service module and any ground station connectors.

There are two connected signal processing units (SPU) on board. They have identical software and hardware to reduce complexity while also reducing footprint size for the electronics processing the sensors signals by allowing them to be stacked. They share the power supply and three signal lines provided by the rockets service module and can communicate via two UART connections (receiving and transmitting) with each other. A solder jumper will be read by software and defines the mode in which they are operate, which is either master or slave. The master-mode SPU is going to be directly connected to the RXSM (REXUS Service Module) and therefore serves the telemetry.

In total twelve stacked biaxial strain gauge rosettes, whose resitance change according to the loads the module encounters, are measured using 16-bit 2000 SPS (Samples per Second) Analog-Digital-Converters (ADCs) connected via a half bridge setup. The same ADCs are used in a different configuration to quantify the temperature at every measurement point. It is imperative, that all ADCs for the strain gauges sample at the same time. We achive that by issuing a sync command on the shared SPI-bus of all straing gauge ADCs at the start. They then continuously sample the differential voltages of the the wheatstone bridge and are being read out be the microcontroller, an STM32.

Setup of the components for signal generation and processing in the HERMESS module.

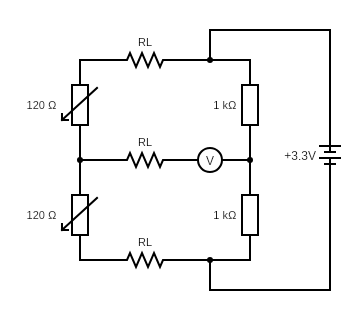

Schematics of the wheatstone measurement bridge.

Schematics of the wheatstone measurement bridge.

The SPU contains two 128MB NOR-flash memory units. They are accessed separately by two different SPI-interfaces of the microcontroller. With this a higher access speed and an improved seperation between metadata and measuring data in the data structure can be achieved.

The casing of the SPU consists of three main parts, which are being assembled vertically with a signal processing unit between each two parts. The SPUs outer borders, which are in contact with the casing parts, are conductive across the top and bottom layer and therefore allow for a single potential of the entire casing. Therefore the casing not only provides a mechanically robust fixture of the electronics in the HERMESS module, but also a protection against electromagnetic influences.

Check out our github repository for the hardware design.

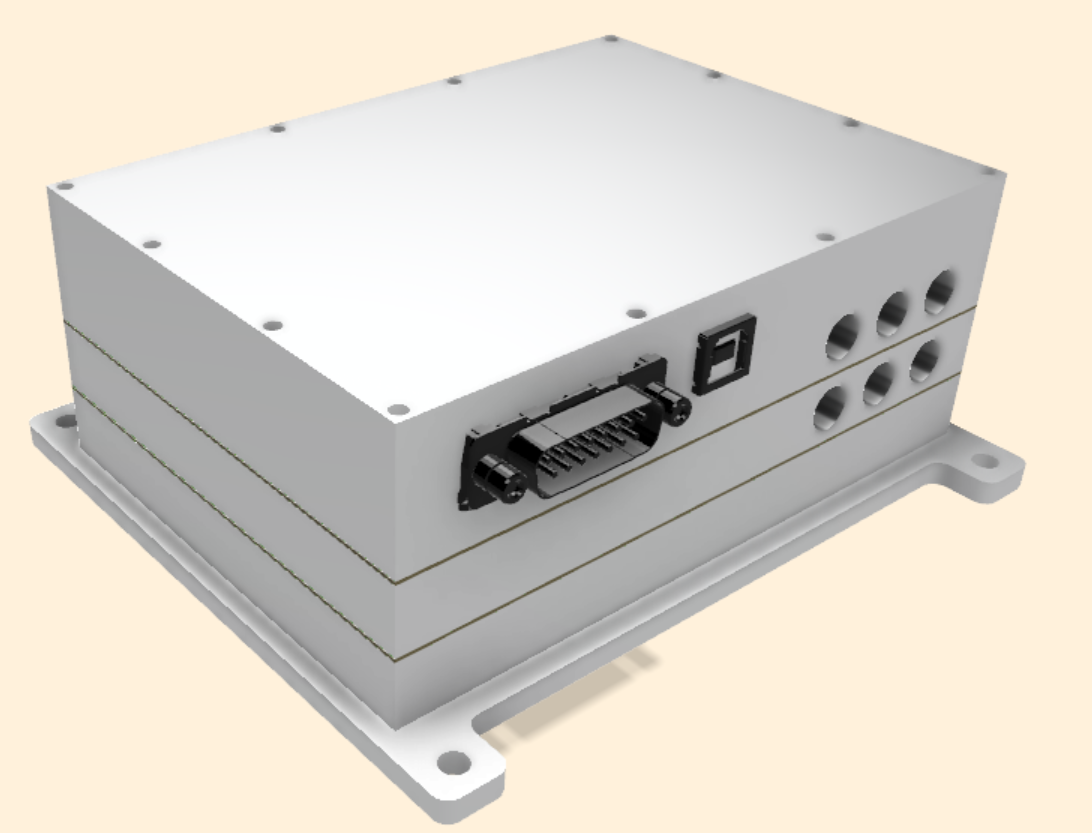

Casing of the signal processing unit.

Casing of the signal processing unit.

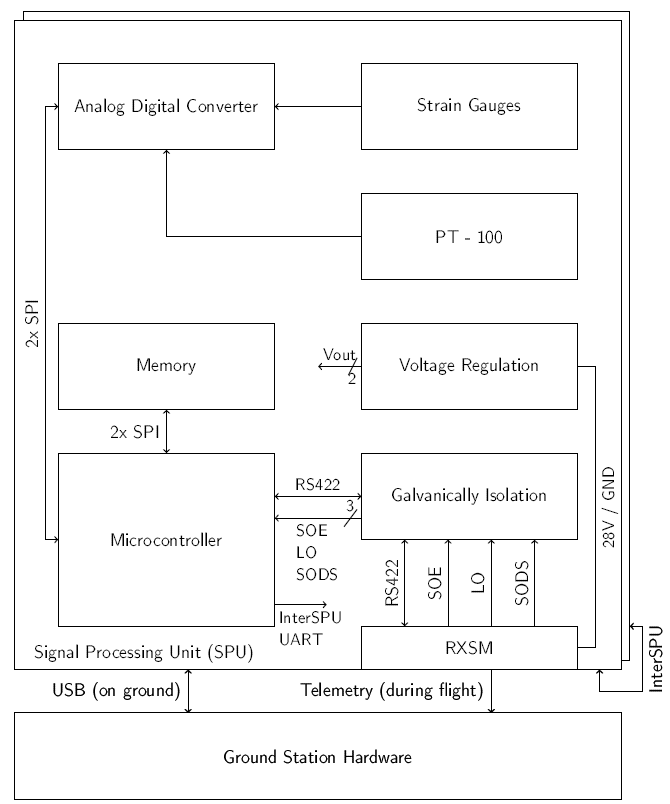

Block diagram of hardware components and interfaces.

Block diagram of hardware components and interfaces.

Because the two signal processing units (SPUs) contain a microcontroller responsible for acquiring, storing and forwarding the measurements, a costum software, developed for both SPUs, is needed to fulfill these tasks. The Microcontroller, an STM32, represents the most crucial actor for this system. C++ is used to program the devices and the source code is publicly available on github. The controllers are run without an operating system and follow a deterministic sequence.

Telemetry covers the communication with our ground station via the provided communication link. In order to be able to send a higher measurement resolution with a fixed data rate, only one of the two SPUs send their data to the ground station, leading to only three evenly spaced measuring points being transmitted. This use case includes compression of the measurements and error handling for a later error correction and recognition.

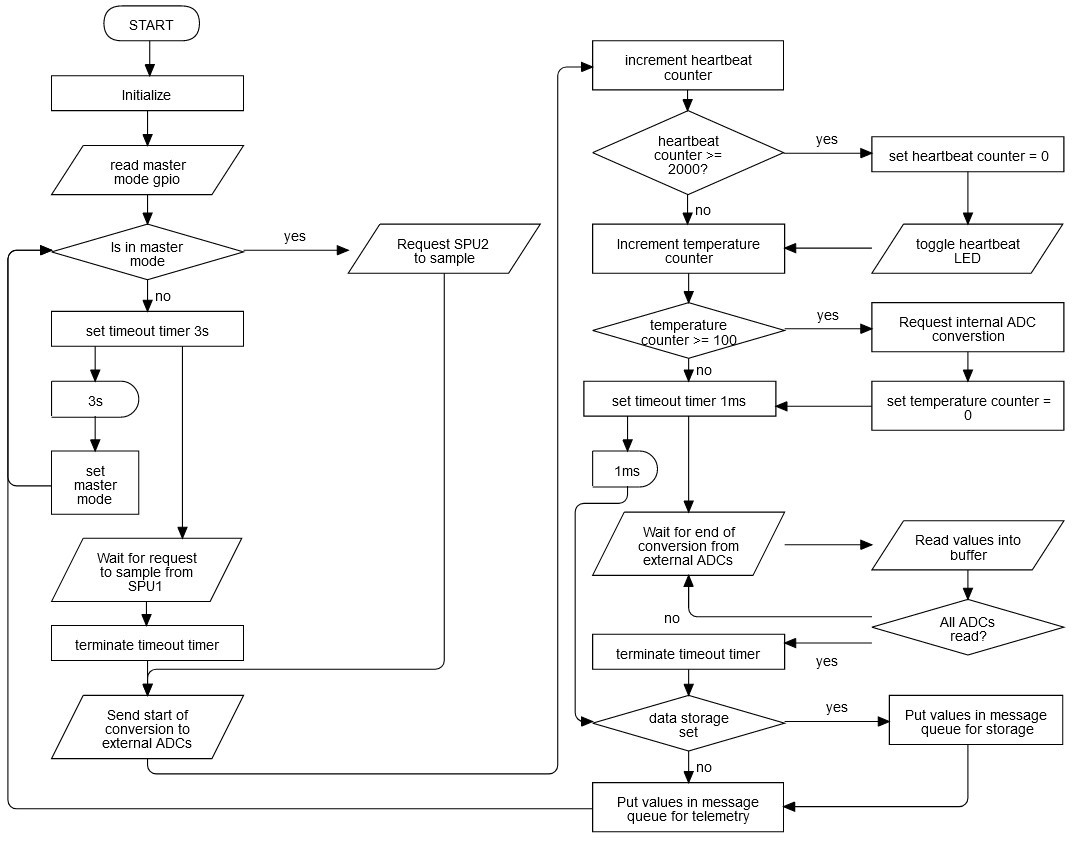

Flow chart of the HERMESS on-board software.

Flow chart of the HERMESS on-board software.

This website uses cookies

In order to optimize our website for you and to be able to continuously improve it, we use cookies. In order to be able to fully use the functions of our website, please consent to their use.

Necessary cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

| Name | Provider | Info | Expiry |

|---|---|---|---|

| cookieinfo | Project HERMESS | Saves the user settings for the cookies. | 90 Tage |

| cms144-session | Project HERMESS | Unique ID that identifies the user's session. | Session |

Preference cookies enable a website to remember information that affects the way a website behaves or looks, such as: B. Your preferred language or the region you are in.

| Name | Provider | Info | Expiry |

|---|---|---|---|

| cms144-language | Project HERMESS | Saves the language version of a website selected by the user. | 90 Tage |

Cookies are small text files that are used by websites to make the user experience more efficient.

According to the law, we can store cookies on your device if they are absolutely necessary for the operation of this site. We need your permission for all other types of cookies.

This site uses different types of cookies. Some cookies are placed by third parties that appear on our pages.

You can change or withdraw your consent from the cookie declaration on our website at any time.

Find out more about who we are, how you can contact us and how we process personal data in our privacy policy.

Please include your consent ID and date when contacting us regarding your consent.